Projects

Abstract of my engineering support in capital spending projects.

| Year: | Project: | Location: |

|

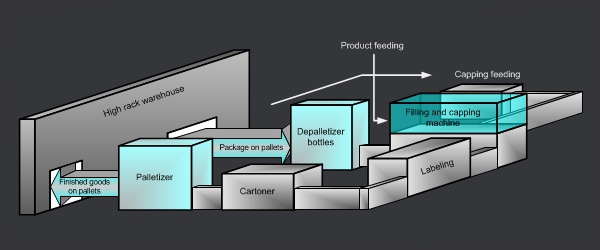

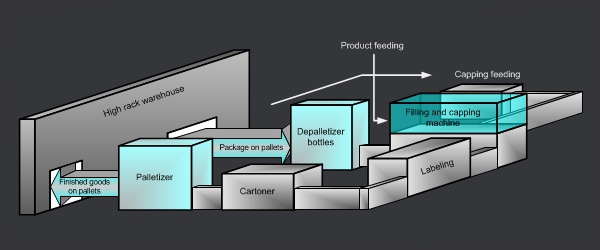

| 2010 | Bottle filling linie for cleaning dilutions | Germany |

| Scope: |

- Clean rooms, process plant, highly purified media, filling & packaging line, manufacturing execution system

|

| Process: |

- Solution and filling

- Packaging and palletizing

- Automatically storage

|

| Year: | Project: | Location: |

|

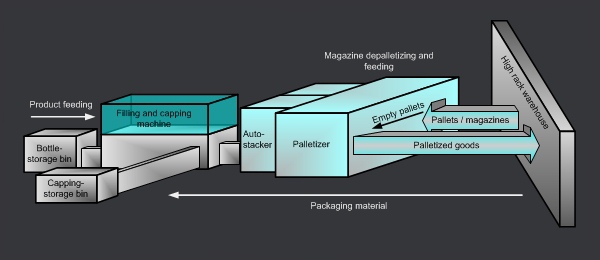

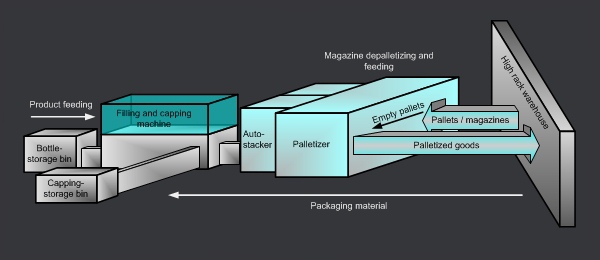

| 2010 | Filling linie, reagents for immunoassay-systems | Germany |

| Scope: |

- Clean rooms, process plant, highly purified media, filling & packaging line, manufacturing execution system

|

| Process: |

- Solution and filling

- Packaging and palletizing

- Semi-automatic storage

|

| Year: | Project: | Location: |

|

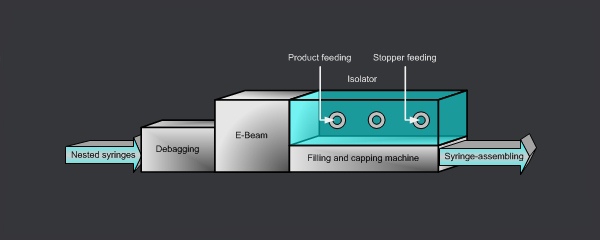

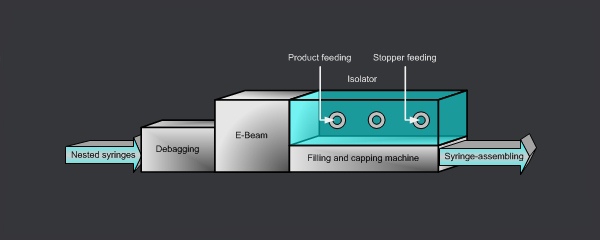

| 2009 | Parenteral processing of presterilized syringes in nests | Germany |

| Scope: |

- Clean rooms, process plant, highly purified media, filling & packaging line, SCADA-system

|

| Process: |

- Manually-feed debagger to unwrap nested, presterilized syringes

- E-Beam-tunnel for surface decontamination of the syringe-tubs

- Removing of sealing foil and fleece liners

- Nest-removing, filling, stopper-positioning and renesting

- Processing of open primary-packaging complete under isolator-protection

|

| Year: | Project: | Location: |

|

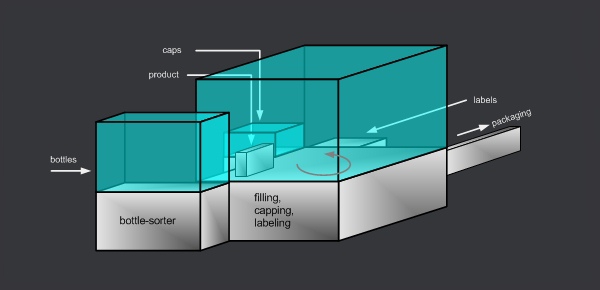

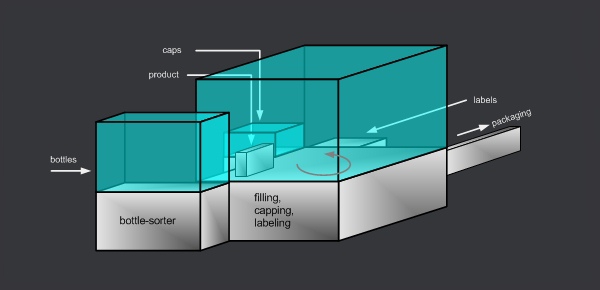

| 2008 / 2009 | Two Bottle-compact-lines for laboratory diagnostics | Schwitzerland |

| Scope: |

- Clean rooms, highly purified media, two filling, packaging & labeling-machines

|

| Process: |

- Infeed of the bottles and caps via vibratory sorting bowls

- Star wheel transport system with three modules for filling, closing & labeling

- Inline-control-stations for all process-steps

|

| Year: | Project: | Location: |

|

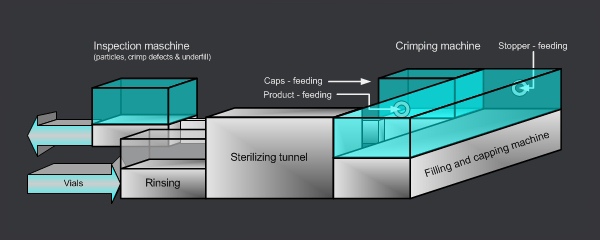

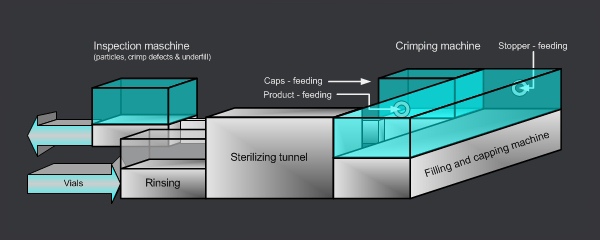

| 2005 / 2008 | Parenteral processing of vials | Germany |

| Scope: |

- Clean rooms, process plant, highly purified media, filling & packaging line, SCADA-system

|

| Process: |

- Manually infeed of tray-loaded vials

- Industrial vial-rinsing with WFI

- Depyrogenization in a fully automatic sterilizing tunnel

- Filling and stopper-positioning under RABS in Class-A-Environment

- In-line closing-machine

- In-line inspection-machine

- Tray-lading for labeling and packaging

|

| Year: | Project: | Location: |

|

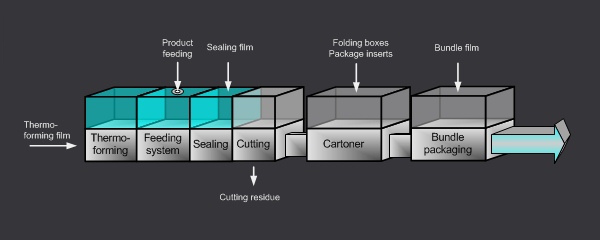

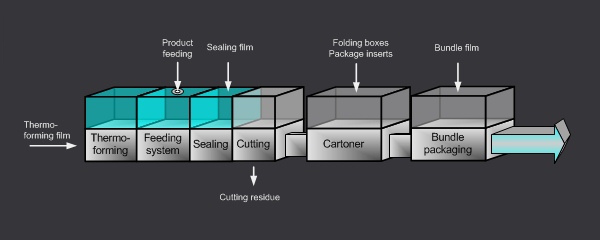

| 2003 | Tablet-processing: Blister, cartoner and bundle module in one unit | Germany |

| Scope: |

|

| Process: |

- Deep drawing station

- High sensitive infeed via stationary lifting column & special containment valve

- Sealing station

- Primary-processing under controlled environment to eliminate dust and cross-contamination

- Extensive monitoring system to control packaging integrity

- In-line cartoner

- In-line bundlepacker

- First steps to realize track & trace and serialisation

|

| Year: | Project: | Location: |

|

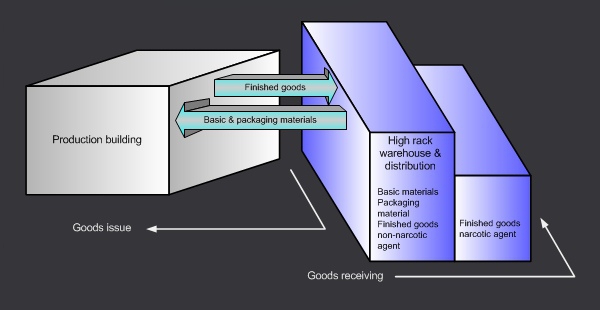

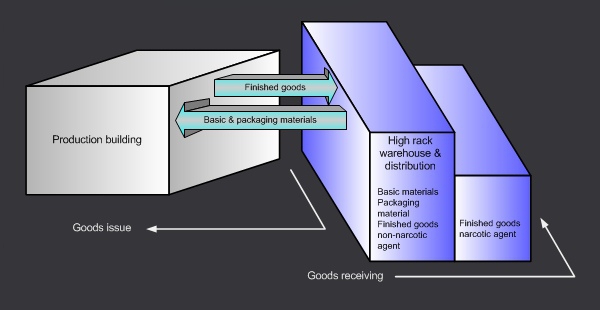

| 1999 | High rack warehouse to store raw materials, packaging materials and drugs | Germany |

| Scope: |

- Infrastructure and outdoor facilities, building, materials handling equipment, warehouse management system - connected to SAP

|

| Process: |

- Goods issue

- Automatic material flow system to support production and distribution

- Special functionality such as pallet exchanger, narcotic agent handling, cold store and monitoring

- Narcotic agent storage and distribution

- Goods receiving

|

| Year: | Project: | Location: |

|

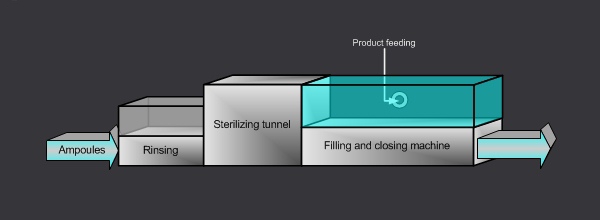

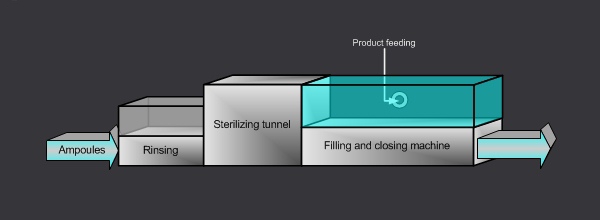

| 1992 | "Classic" Ampoule production line | Germany |

| Scope: |

- Clean rooms, process plant, highly purified media, filling, sealing and coding line

|

| Process: |

- Manually infeed of tray-loaded ampoules

- Cleaning (inside, outside, ultra sonic) with WFI

- Depyrogenization in a fully automatic sterilizing tunnel

- Filling, sealing and coding in Class-A-environment

- Tray-loading for successional secondary processing e.g. thermal sterilization, optical inspection, leak inspection, labeling and packaging

|

Top

Top Home

Home Sitemap

Sitemap